roughing end mill diagram

Seco Tools LLC Niagara Cutter N79600. These lower the shock load during the cutter rotation both enabling a heavier cutting load.

The Complete Guide To Plunge Milling And Roughing

Our online store is your easy one-stop source for all things metalworking and were positive we can help you find the perfect quality solutions for all your machine shop needs.

. Corner radius end mills have a rounded cutting edge and are used where a specific radius size is required. A premium rupture resistant substrate is the foundation to. Roughing Finishing End Mills The Triple Threat tool is a multi-patented three flute high performance carbide end mill designed to finish and rough in aluminum and non-ferrous metals.

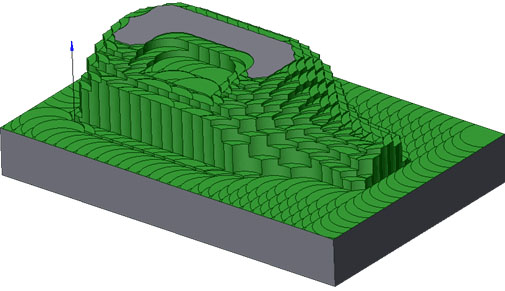

CNC machining is a subtractive process that uses rotational cutting tools called end mills to remove material. An end mill while similar in appearance to a drill bit is far more versatile. Endmills are available in a wide variety of lengths diameters flutes and types and are chosen according to the material they are cutting and the surface finish required for the project.

Cutting edges are only on a top. 1High quality material of carbide2Wear-resisting and Not easy to stick milling cutter3High efficiency of chip removal4Speed machining and High degree of. Figure 11 shows surface temperature variation of the work-rolls in the roughing mill where they are cooled using two water sprays with convection heat transfer coefficient of 30 000 W m 2 K 1 and heat transfer coefficient for the film cooling region is taken as 6000 W m 2 K 1.

However in practice the terms bit and end mill are often used interchangeably. The high shear 45 degree helix and improved inter-flute geometries enhanced chip evacuation and permit increased chip loads as well as aggressive feed rates. In diameter sizes from 18 to 3.

The tooth design allows for little to no vibration but leaves a rougher finish. Side milling curved surface milling and drilling are possible only by one. High quality roughing end mills for sale.

The SSDH series achieves superior chip flow and evacuation through the introduction of chip-release flute form technology and a unique inter-flute helical transition all within a patent pending design. The spiral flute end mill compared to a straight flute does a similar function. Available in stub to extra long lengths.

Milling cutter A rotary cutting tool having many cutting edges on the periphery or an end face of a cylinder and a cone. Sign in for your price 9622 each. Design that Virtually Eliminates Flute Packing and Obstruction.

The dimensions of the components are listed in Table 1. Normally a 20 reduction in effective horsepower is used. It is possibler to gash a rougher on a tool cutter grinder or even a pedestal grinder with a hand-formed saucer.

Roughing End Mills - Cobalt and High Speed Steel. A poor machine-to-tool connection can cause tool runout pullout and scrapped parts. Some end mills with fewer flutes are called roughing end mills as the fewer flutes mean.

66 μm after about 10 hours passed. Roughing End Mills for Aluminium Roughing End Mills for Al-alloy High speed milling over 6000ccmin ded. Generally speaking the more points of contact a tool holder has with the tools shank the more secure the connection.

Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill. Login Dear Customers Our supplier HTC is having substantial problems with. 1 C-SRA C-MRA C-SRARB 616mm 25mm 655 Õ 5 10 30 50 70 1000 2000 3000 4000 5000 6000 Roughing End Mills for Aluminium Wide variation Highly efficient Roughing.

Ad Browse discover thousands of brands. Their extreme hardness means they are brittle so a highly rigid setup such as a CNC machine is necessary to prevent the end mill from. Carbide Square End Mills.

Figure 7 shows the tool wear of the end mill after about 0 10 and 20 hours passed in real gear machining. For assistance with finding the right tools or any other questions please feel free to call our customer support team at 800-221-0270 or use our. Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material.

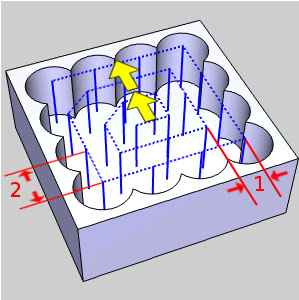

Tertiary 3rd Additional relief clearance provided adjacent to the secondary angle. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. These tools are designed specifically for aluminum although they are suitable for a very broad range of materials having up to high tensile strengths.

This feature is produced by a dish angle produced on the cutter. Niagara Cutter Roughing End Mill - REM445 Series Cobalt High Speed Steel Material TiCN Square End 34 in Mill Diameter 4 Flutes 2 in Length of Cut. 2 roughing mill in CSC and are summarized in.

Drill A tool for drilling. Large temperature variations occur at the surface region of the work-roll owing to severe temperature. The rolling parameters were adopted from the No.

Drill plunging axially on left endmill cutting laterally. Secondary 2nd angle 14 17 degrees Relief adjacent to the cutting edge. Concave Small hollow required on the end face of an Endmill.

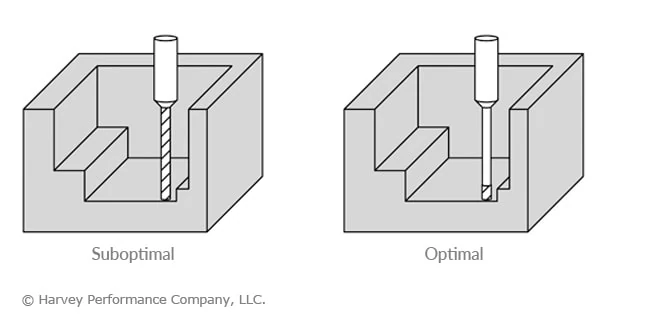

Proper running parameters have less of an impact in suboptimal tool holding situations. Available in carbide cobalt and HSS substrates. End mill A multi-functional tool which has cutting edges on the periphery and an end face.

Coarse-Pitch Roughing Aluminum CPRA CPRA series milling cutters are coarse-pitch HSSCo8 High-Speed Steel with 8 cobalt 3-flute 37 helix roughing end mills. Since the radial relief angle of end mill is 11 degree the diminution Δr of radius of end mill is 34 μm tan 11 deg. Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions.

Hydraulic and shrink fit tool holders offer. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. Read customer reviews find best sellers.

The length of tool wear of the cutting edge was about 34 μm. Roughers are one of the hardest tools to get right on a tool cutter grinder as the inside of the flute the top face has to be ground where-as a conventional end mill is sharpened by grinding the outside of the cutter. A roughing end mill the type with a wavy corncob outer flute cuts into the part at a higher ratio to the rotation.

Corner chamfer end mills have an angled cutting edge and are used. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing.

End Mills cut rotationally in a horizontal or lateral side to side direction whereas a drill bit only cuts straight down vertically into the material.

Taper Ball End Mill For High Accuracy Rib Slotting Eb4hr Ath Moldino The Edge To Innovation Moldino Tool Engineering Ltd

The Secret Mechanics Of High Feed End Mills In The Loupe

Sanrico Carbide End Mill End Mill Wood Drill Bits Non Ferrous Metals

Basic End Mills Technical Information Msc Industrial Supply Co

Pin By Angelique Pfeiffer On Framing Table Saw Blades Rough Sawn Lumber Writing

End Mill An Overview Sciencedirect Topics

Hpmt Sc Roughing Endmill G6110 Kyocera Unimerco

Atc Rough Cutting End Mill 218 2 Indexable Milling Insert Holder Indexable Milling Insert Holder Milling Bar Shenzhen Ussharp Cutting Technology Co Ltd

Roughing Chip Breaker Bits 4 Flute F4zc45 End Mills Drills Frezycnc Eu

Roughing End Mill Kyocera Unimerco

A Milling Technique For Roughing That Utilizes A Lower Rdoc And Higher Adoc Than Traditional Milling Hem Distributes Wear Even Efficiency Cnc Training Milling

Roughing Mill An Overview Sciencedirect Topics

The Complete Guide To Plunge Milling And Roughing

Solid Carbide End Milling Solid Carbide End Mill For Roughing And Finishing Of Aluminum